Beeprog+ programmer is a professional universal programming device for development, service, production, and mobile applications. chinese BeeProg+ Universal Programmer is A Universal Programmer for Socket-Based and In-Circuit Programming. china factory beeprog+ can update by email.

beeprog+ Universal programmer in chinese market updated by email, can't be updated by internet, or the machine will be damaged. The Chinese beeprog+ programmer is used version, PCB board still nice and work fine.

The BeeProg+ from ELNEC is built to meet the strong demands of the small manufacturing and developer community for a fast and reliable universal programmer. It supports all types of silicon technologies of today, and also tomorrow’s programmable devices, without a family-specific module. Using a built-in in-circuit serial programming (ICSP) connector, the programmer is able to program ISP capable chips in circuit.

BeeProg+ Universal Programmer for choose:

Option 1: OEM beeprog+ programmer( can't work with internet)

Option 2: BeeProg+ Universal programmer ( original old stock)

Beeprog+ highlights:

1. BeeProg+ isn't only a programmer, but also a tester of TTL/CMOS logic ICs and memories. Furthermore, it allows generation of user-definable test pattern sequences. Obd2cartool.com BeeProg+ features very fast programming due to high-speed FPGA driven hardware and execution of time-critical routines inside of the programmer. It interfaces with the IBM PC compatible or higher, portable or desktop personal computers through USB (2.0/1.1) port or any standard parallel (printer) port. The programmer can utilize the power of both USB high-speed port and IEEE1284 (ECP/EPP) high-speed parallel port. Support of both USB/LPT port connections gives you the choice to connect the BeeProg+ programmer to any PC, from the latest notebooks to older desktops without a USB port.

2. BeeProg+ supports all Microchip device families, plus thousands of additional devices. In addition to the comprehensive component support and extremely fast programming, the Beeprog+ offers a rugged housing which is suitable for industrial applications.

3. BeeProg+ programs nearly all available chips like: EPROMs, paged EPROMs, EEPROMs, serial EEPROMs, FLASH memory (NOR and NAND), bipolar PROMs, NVRAMs, Microcontrollers, GALs, PALCEs, PLD's, SPLDs, CPLDs, EPLDs, Firmware HUBs, MCU, standard logic.

Hardware Features

FPGA based, totally reconfigurable 48 powerful TTL pin drivers provide H/L/pull_up/pull_down and read capability for each pin of socket. Advanced pin drivers incorporate high-quality high-speed circuitry to deliver signals without overshoot or ground bounce for all supported devices. Improved pin drivers operate down to 1.8V so you'll be ready to program the full range of advanced low-voltage devices.

The programmer performs device insertion test (wrong or backward position) and contact check (poor contact pin-to-socket) before it programs each device. These capabilities, supported by over-current protection and signature-byte check help prevent chip damage due to operator error.

The built-in self test capability allows the software to thoroughly check the health of the programmer.

Built-in protection circuits eliminate damage of programmer and/or programmed device due to environment or operator failure. All the inputs of the BeeProg+ programmer, including the ZIF socket, connection to PC and power supply input, are protected against ESD up to 15kV.

BeeProg+ programmer performs programming verification at the marginal level of supply voltage, which improves programming yield, and guarantees long data retention.

Various socket converters are available to handle device in PLCC, JLCC, SOIC, SDIP, SOP, PSOP, SSOP, TSOP, TSOPII, TSSOP, QFP, PQFP, TQFP, VQFP, QFN (MLF), SON, BGA, EBGA, FBGA, VFBGA, UBGA, FTBGA, LAP, CSP, SCSP, LQFP, MQFP, HVQFN, QLP, QIP and other packages.

Software Features

BeeProg+ is driven by an easy-to-use control program (called PG4UW) with pull-down menu, hot keys and on-line help. Selecting of device is performed by its class, by manufacturer, or simply by typing a fragment of vendor name and/or part number. The control program is a 32-bit application for WINDOWS 95/98/Me/2000/NT/XP/2003/XPx64/Vista/7

Standard device-related commands (read, blank check, program, verify, erase) are boosted by test functions (insertion test, signature-byte check), and some special functions (auto-increment, production mode - start immediately after insertion of chip into socket).

All known data formats are supported. Automatic file format detection and conversion is performed during loading of file.

The rich-featured auto-increment function enables one to assign individual serial numbers to each programmed device, or to simply increment a serial number, or to read serial numbers or any device identification signatures from a file.

The software also provides extra information about the device to be programmed, including drawings of all available packages and an explanation of chip labeling (the meaning of prefixes and suffixes on part numbers) for each supported chip.

The software also provides complete information for ISP implementation, including a description of ISP connections for the currently selected chip, recommended target design around in-circuit programmed chip, and other necessary information.

The remote control feature allows the PG4UW software to be controlled by another application – either using .BAT file commands or using DLL file. Examples of using the DLL file are provided in C, Pascal, VBASIC, .NET, and a manual are part of standard software delivery.

Jam files of JEDEC standard JESD-71 are interpreted by Jam Player. Jam files are generated by design software which is provided by manufacturer of respective programmable device. Chips are programmed in-ZIF or through ISP connector (IEEE 1149.1 Joint Test Action Group (JTAG) interface).

VME files are interpreted by VME Player. VME file is a compressed binary variation of SVF file and contains high-level IEEE 1149.1 bus operations.

SVF files are interpreted by SVF Player. SVF file (Serial Vector Format) contains high-level IEEE 1149.1 bus operations. SVF files are generated by design software which is provided by manufacturer of respective programmable device. Chips are programmed in-ZIF or through ISP connector (IEEE 1149.1 Joint Test Action Group (JTAG) interface). VME files are generated by design software which is provided by manufacturer of respective programmable device. Chips are programmer in-ZIF or through ISP connector (IEEE 1149.1 Joint Test Action Group (JTAG) interface).

Multiple devices are possible to program and test via JTAG chain: JTAG chain (ISP-Jam), JTAG chain (ISP-VME), JTAG chain (ISP-SVF) or JTAG chain (ISP-STP).

Attaching of more BeeProg+ programmers to the same PC (through USB port) is achieved a powerful multiprogramming system which supports as many chips as are supported by BeeProg+ programmer and without an obvious decrease in programming speed. Each programmer works independently and can program different chips, if necessary.

File Options

The File options page allows you to set file masks, auto-reload of current file and choose file format recognizing for loaded files. Automatic file format recognition will accept mostly all available file formats - Binary (RAW), Intel (Extended) HEX, MOTOROLA, MOS Technology, Tektronix, ASCII space, JEDEC and POF.

Language

The Language page allows you to select another language for user interface, including menu, buttons, dialogs, information and messages.

Device Operations

You can select target device by its class, by manufacturer, or simply by typing a fragment of vendor name and/or part number.

Additional information about selected device may be displayed by pressing <Ctrl + F1> or Device info button.

Drawings of all available packages are provided.

The software also provides an explanation of chip labeling (the meaning of prefixes and suffixes at the chips) for each supported chip.

The software provides full information for ISP implementation, including a description of ISP connector pins, recommended target circuit design around the chip to be programmed, and other necessary information.

Device Operation Options

All settings of this command are used for programming process control. This is a flexible environment which contains items associated with current device and programmer type.

View/Edit Buffer

This window is used for buffer manipulation, block operation, filling a part of buffer with string, erasing, checksum and of course editing and viewing with other items (find and replace string, printing, etc.).

Program

This command allows programming of the entire device, or just a portion, using data in the buffer. The control program reports a result of this action to the Log window. Information about device operation options and optional settings are displayed in window below. Pressing button Device operation options (or Alt + O) you could change Device operation options. Pressing button on the top of right panel (or Alt + S) you could change optional settings.

Serialization

With serialization mode is activated a specified value is automatically inserted into a predefined address in the buffer before programming each device. When additional devices are programmed, the serial number value is changed for each device automatically and inserted into the buffer before programming, so each device has a unique serial number.

There are two types of serialization: “Incremental mode”, and “From-file mode”.

Statistics

Statistics gives the information about actual count of device operations which were perfromed on selected type device. If one device is corresponding to one device operation, e.g. programming, the number of device operations will be equal to number of programmed devices. The next function of statistics is Count down. Count down allows checking the number of device operations and then number of devices on which device operations have to be done.

Automatic YES!

This command is used for setting Automatic YES! mode. In this mode you just put a device into ZIF socket and the last operation will be repeated automatically. BeeProg+ automatically detects an insertion of a new device and runs last executed operation without pressing any key or button.

Project Files

Project files contains device configurations (name and manufacturer of selected device, device operation options of this device), data of buffer, user interface configuration, description of project, author and date of project creation. This feature allows you to eliminate operation errors, because operation can not modify any parameters of programming. It's so easy: load project and then only insert devices to ZIF socket.

Remote control support of PG4UW software

The remote control feature allows BeeProg+ software functions to be controlled by other application – either using .BAT file commands or using DLL file. For example, to control BeeProg+ automatically from within MPLAB IDE, a simple .BAT file could be entered as a Post-Build Step in Build Options:Custom Build.

Two basic ways to remote control the Pg4uw application:

1: Controlling PG4UW with remote control program (example: program PG4UWrem.exe - part of PG4UW software delivery).

2: Controlling PG4UW with command line remote control program PG4UWcmd.exe (also part of PG4UW software delivery).

Because the TCP/IP mode is used for sending messages between PG4UW software and the remote software, the worldwide control of PG4UW over Internet is possible.

JTAG daisy chain

Connecting multiple devices via their JTAG ports is commonly referred to as JTAG daisy chaining. PG4UW software supports programming and testing multiple devices via their JTAG ports in JTAG daisy chaining.

The pins TMS and TCK are connected directly, but the pin TDO from one device goes to the pin TDI of next device. When using a JTAG chain with mixed voltage devices, extra care must be taken to ensure the integrity between the devices. The devices in JTAG chain can be programmed and tested. It is possible to choose JTAG chain (ISP-Jam) for Altera and Xilinx devices or JTAG chain (ISP-VME) for Lattice devices.

Diagnostics

These functions execute a self test with or without the BeeProg+ diagnostic POD. Run the diagnostic functions as often as desired to ensure correct operation of the programmer.

OBD2cartool After-Sale Service:

Technical Support: Free

Whatsapp:+86-13537734676

Live Support: Chat with us online

Email: obd2cartool@hotmail.com

Yahoo: obd2cartool@yahoo.com

Skype: great2obd

If you have any problem, please do not hesitate to contact us.

Wholesaler Discount: If you are wholesaler or reseller, pls send email to obd2cartool@yahoo.com, we will give you best discount for long-term cooperate.

Payment Terms: We accept payment by paypal, western union, money gram and bank transfer.

Shipment Note:

1. All our free shipping items can track it online after delivery, you don't worry about your order status.

2. Express Delivery we will send to you with DHL,EMS,UPS,FEDEX,TNT..., please give us a valid delivery phone number, and also a full and accurate shipping address.

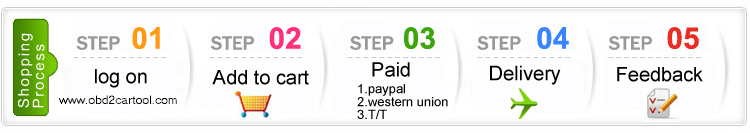

How to make order on OBD2cartool.com?

Notice: After you place order, pls reply confirm email send by obd2cartool@yahoo.com asap for us to arrange ship for you, thanks