QUICK 7720 BGA rework station is china brand BGA repairing platform, with microprocessor control, it is designed for BGA / CSP and other SMT surface mount components for repair and welding, and welding by using a dedicated software -BGASoft control the entire process, recording all of its information, to meet the modern electronics industry higher technical requirements, QUICK 7720 BGA rework system is one of the most valuable electronic tools electronics industry.

QUICK 7720 BGA rework station QUICK 7720 BGA repairing platform

QUICK 7720 BGA rework station infrared heating and hot air heating in harmony together. In order to obtain optimum control of the welding process can be repeated and non-destructive production of PCB temperature, QUICK 7720 BGA rework station provides maximum power adjustable heating power of 3500W, the top heater using hot air heating, infrared heating bottom preheating, a combination of hot air heating, hot air locally heating the bottom of PCB BGA corresponding part, and to control the temperature profile, the corresponding part of the infra-red heating the PCB board, to control the entire preheating temperature, to prevent local deformation of the PCB, the heat distribution. In order to ensure uniform heat distribution and appropriate peak temperature, in order to achieve high reliability of lead-free solder. Infrared heating part according BGA different locations on the PCB, and is free to move in the X-axis. Using a frame-shaped structure movable PCB holder and can be placed shaped plate support bars, consistent with the cross arm is connected to the bottom of the support bar, easy to place each PCB when applicable larger size PCB.

QUICK 7720 BGA rework station also comes with integrated process control software and show the program to facilitate the realization of multiple control. The most significant users can meet the requirements of BGA rework, especially in the lead-free rework to better reflect its uniqueness.

QUICK 7720 Applications:

QUICK 7720 BGA rework station is suitable for laptops, desktops, servers, industrial control panels, switches and other products for the welding process and rework BGA, CSP, QFP, PLCC packages and other devices, removal or repair, and can meet the requirements of lead-free soldering .

The main technical parameters:

Power Specifications 220V, 50Hz, 3KW

Smallest chip size 2 * 2mm

The maximum chip size 60 * 60mm

Preheat the bottom of radiation size 330 * 360mm

Hot air heating temperature 500 ℃ (max)

The bottom of the preheating temperature of 500 ℃ (max)

Top hot air heating power 700W

The bottom of the hot-air heating power 700W

Bottom preheating power 400W * 4 = 1600W (infrared heating)

Adjustable side wind speed cooling fan ≦ 3.5 m³ / min

K-type sensor 3

Communication standard RS-232C (available with PC)

Dimensions 650 (L) * 570 (W) * 500 (H) mm

Equipment weight about 43Kg

OBD2cartool After-Sale Service:

Technical Support: Free

Whatsapp:+86-13537734676

Live Support: Chat with us online

Email: obd2cartool@hotmail.com

Yahoo: obd2cartool@yahoo.com

Skype: great2obd

If you have any problem, please do not hesitate to contact us.

Wholesaler Discount: If you are wholesaler or reseller, pls send email to obd2cartool@hotmail.com, we will give you best discount for long-term cooperate.

Payment Terms: We accept payment by paypal, western union, money gram and bank transfer.

Shipment Note:

1. All our free shipping items can track it online after delivery, you don't worry about your order status.

2. Express Delivery we will send to you with DHL,EMS,UPS,FEDEX,TNT..., please give us a valid delivery phone number, and also a full and accurate shipping address.

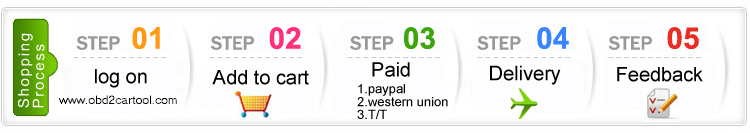

How to make order on OBD2cartool.com?

Notice: After you place order, pls reply confirm email send by obd2cartool@hotmail.com asap for us to arrange ship for you, thanks